Learn how it boosts factory floor connectivity and reliability.

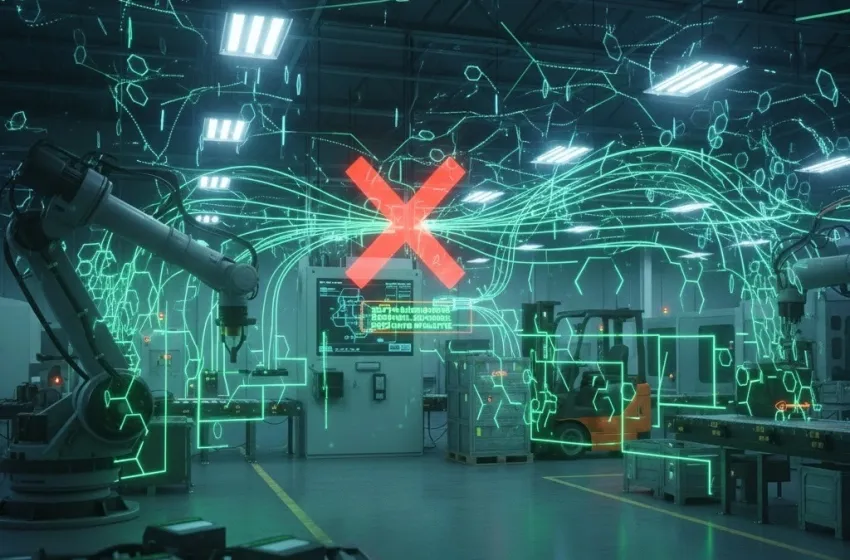

Mesh Networking for Industrial IoT: The Blueprint for Resilient Factory Floor Connectivity

The relentless drive toward Industry 4.0 and the transformative power of the Industrial IoT (IIoT) have placed an unprecedented demand on network infrastructure. Modern industrial environments—from vast oil fields to complex manufacturing plants—require the real-time collection and analysis of massive datasets to enable critical functions like predictive maintenance, asset tracking, and process optimization. Traditional wired and star-topology wireless communication systems often buckle under this pressure, failing to deliver the required coverage, scalability, and, most critically, resilience in challenging operating conditions. The solution lies in a paradigm shift to Mesh networking, a decentralized, dynamic, and inherently robust network architecture that is fast becoming the backbone of reliable factory floor connectivity.

The Anatomy of Industrial Networking Challenges

The typical industrial setting presents a minefield of connectivity issues that severely limit the efficacy of standard network technologies:

- Physical Obstruction and Interference: Dense materials, metal machinery, large moving equipment, and heavy-duty concrete walls are ubiquitous. These elements create significant signal attenuation and multi-path fading, resulting in "dead zones" and inconsistent connectivity.

- Dynamic Environments: Industrial layouts change frequently as production lines are reconfigured or machinery is moved. A centralized, fixed network infrastructure cannot adapt quickly, leading to costly re-cabling or network downtime.

- Scale and Density: The number of sensors and actuators in a modern IIoT deployment can easily reach into the thousands. Traditional centralized networks struggle to manage the traffic load, leading to high latency and bottlenecks.

- Mission-Critical Reliability: A momentary network failure in an industrial setting can result in lost production, damaged equipment, or safety hazards. Zero tolerance for downtime mandates a solution with built-in redundancy and automated recovery.

The limitations of conventional star-based Wi-Fi or cellular networks, which rely on a single central access point, become glaringly apparent here. A single point of failure can cripple an entire operation, making them inadequate for mission-critical applications where uninterrupted operation is non-negotiable.

Understanding the Mesh Networking Paradigm

Mesh networking is a revolutionary approach to wireless communication that fundamentally solves the resilience challenges inherent in industrial settings. Unlike star networks where every device communicates solely with a central hub, a Decentralized network architecture is employed where every device, or 'node,' acts as an independent router, actively participating in the distribution of data across the network.

1. Decentralized Network Architecture: The Core of Resilience

In a mesh topology, devices relay data for each other, creating a vast, multi-hop web of connections. This is the essence of the Decentralized network architecture.

- Redundant Paths: Each node typically has multiple pathways to reach the central gateway (the point connecting the IIoT network to the broader enterprise or cloud system). If the direct path between a sensor and the gateway is blocked, the data automatically "hops" through neighboring nodes until it finds an open route.

- Extended Range: This multi-hop relaying drastically increases the effective range of the network. Low-power, short-range endpoint devices, which would normally struggle to reach a distant gateway, can reliably transmit their data by leveraging closer, more powerful repeater nodes. This is vital for vast industrial campuses or facilities with complex physical barriers.

- Load Distribution: By spreading the communication load across numerous nodes, the network avoids the bottlenecks that plague centralized systems. This is particularly crucial for supporting the high data throughput required for real-time applications like machine vision and control.

2. Self-Healing Networks: The Power of Autonomy

The most transformative feature of mesh networks is their ability to be self-healing networks. This refers to the network's autonomous capability to detect a failed link, a blocked signal, or a dead node, and instantly reroute traffic around the problematic area without human intervention or any noticeable service disruption.

The routing protocols embedded within the mesh nodes—such as the RPL (Routing Protocol for Low-Power and Lossy Networks)—continuously monitor link quality and dynamically calculate the optimal, most efficient, and most reliable path for every data packet.

- Dynamic Reconfiguration: If a forklift temporarily blocks a line-of-sight signal, or if a battery-powered sensor goes offline, the network automatically and instantaneously updates its routing tables, ensuring connectivity remains intact. This is the bedrock of resilience for any mission-critical IIoT deployment.

- Increased Uptime: The ability to recover from a single or even multiple concurrent failures dramatically increases the overall network uptime, directly translating into higher operational efficiency and reduced unplanned downtime.

The Transformative Benefits of Mesh for Industrial IoT (IIoT)

The robust characteristics of Mesh networking align perfectly with the rigorous demands of Industrial IoT (IIoT), offering tangible benefits that drive smart manufacturing and operational excellence.

1. Unmatched Reliability and Resilience

The multi-path, self-healing networks design is the ultimate guarantor of network reliability. In the unforgiving electromagnetic environment of a factory floor connectivity system, where interference and physical obstructions are constant threats, mesh networks provide the essential redundancy that traditional networks lack. Data loss is minimized, and the continuity of real-time monitoring and control is preserved, ensuring the integrity of mission-critical processes.

2. Superior Scalability and Flexible Deployment

Scaling an IIoT system with a star-topology typically involves installing new access points and running new cables, which is a costly and disruptive process. A mesh network, conversely, is inherently scalable.

- Ease of Expansion: Adding a new sensor or machine to the network is as simple as powering it on. The new device automatically self-configures, discovers its neighbors, and begins participating in the data relay process, instantly extending both coverage and capacity.

- Reduced Infrastructure Cost: Since every powered device can serve as a repeater, the need for extensive, expensive, and inflexible wired backhaul infrastructure is significantly reduced. This makes deploying connectivity across large, geographically dispersed, or remote industrial sites, like mines or container ports, far more cost-effective.

3. Optimized Power Consumption

While continuous data relaying might suggest high power draw, modern mesh technologies (such as Bluetooth Mesh, Zigbee, and Thread) are optimized for low-power operation. Battery-powered endpoint nodes only need to communicate with the nearest node, often just a few meters away, conserving their battery life. The mains-powered nodes (like smart lights or fixed machinery controllers) take on the heavier burden of data relaying, creating an energy-efficient, tiered structure.

4. Real-Time Data and Low Latency

The dynamic routing inherent to a mesh system ensures that data packets are always sent via the fastest available path. By eliminating the bottleneck of a single centralized access point, the network can maintain exceptionally low latency, which is essential for closed-loop control systems, robotic coordination, and immediate fault detection in real-time industrial applications.

Implementing Mesh Networking in the IIoT

The deployment of a Mesh networking solution for Industrial IoT (IIoT) is a structured process that leverages its decentralized network architecture for maximum impact.

1. Node Types and Roles

A successful IIoT mesh network typically comprises three distinct types of nodes, ensuring efficient data collection and relaying:

- Endpoint Nodes: These are typically low-power, battery-operated sensors (e.g., temperature, vibration, pressure) or actuators. Their primary role is to gather or act on data. They only transmit data to a nearby repeater or gateway, conserving energy and extending battery life.

- Repeater Nodes (or Relay Nodes): These are usually mains-powered devices, such as smart lighting fixtures, larger machinery control units, or dedicated repeaters. They are the backbone of the multi-hop network, responsible for receiving data from endpoint nodes and relaying it toward the gateway, effectively extending the wireless communication range.

- Gateway Nodes: These are the access points that bridge the local mesh network to the external network (the internet or a private cloud/data center). They aggregate data from the repeater and endpoint nodes, handle network management, and apply edge computing functions before transmission.

2. Selecting the Right Protocol

The choice of wireless communication protocol is critical and depends on the application's specific needs for range, data rate, and power consumption:

- Bluetooth Mesh: Excellent for high-density, low-power applications such as smart lighting control and in-building asset tracking on the factory floor connectivity. It offers a good balance of data rate and power efficiency.

- Zigbee/Thread: Widely used in home and building automation, these protocols are also robust for industrial control systems, providing solid resilience and energy efficiency for stationary sensor networks.

- Wi-SUN (Wireless Smart Utility Network): Designed for large outdoor infrastructure, this protocol provides long-range, high-reliability mesh capabilities, ideal for utility monitoring, pipeline surveillance, or large logistics yards.

3. Security Considerations

A decentralized network architecture introduces more points of entry, making robust security paramount. Modern mesh protocols incorporate advanced security features:

- Encryption and Authentication: All communication within the mesh network must be secured with multi-layer encryption (e.g., AES-128) and strong device-level authentication to prevent eavesdropping and unauthorized access.

- Network Key Management: Mesh protocols employ sophisticated key management to segment the network and restrict access. If one section of the network is compromised, the entire system's integrity is protected.

- Over-the-Air (OTA) Updates: Secure, remote firmware updates are essential to patch vulnerabilities across the vast number of devices that constitute the IIoT network.

The Future of Industrial Automation

The fusion of Mesh networking with Industrial IoT (IIoT) represents a fundamental step toward achieving true Industry 4.0 capabilities. By providing self-healing networks with inherent resilience and massive scalability, mesh topologies eliminate the critical failure points of legacy systems. The distributed nature of the decentralized network architecture ensures that data is consistently available for real-time analysis, predictive maintenance, and operational control, regardless of the harsh, complex, and dynamic conditions on the factory floor connectivity. As the industrial landscape continues to evolve, mesh networking is poised to be the non-negotiable standard for reliable, high-performance wireless communication in every smart industrial enterprise.